In today's context of rapid urbanization and the integration of landscape aesthetics, outdoor lighting solutions have long surpassed the simple function of "illumination." It is a comprehensive discipline encompassing optical design, thermal management science, materials engineering, and intelligent control. As a high-tech enterprise with over a decade of industry experience, Everlite LED Lighting Co., Limited. consistently focuses on cutting-edge research and manufacturing, precisely matching technical solutions to environmental needs through in-depth exploration of light and shadow principles.

I. Precise Light Distribution: The Soul of Outdoor Lighting

The core challenge of outdoor lighting lies in effectively distributing light energy in vast and open spaces. The quality of the light distribution scheme directly determines the lighting quality and energy efficiency.

Uniformity of Light Distribution: An excellent outdoor lighting solution must eliminate the "zebra stripe" effect, ensuring smooth brightness transitions on the ground or illuminated surfaces. During the R&D process, Everlite focuses on the total reflection efficiency of the lens, using calculus-based optical design to direct light according to actual application scenarios (such as roads, squares, or building facades).

Glare Control and Light Pollution Prevention: With the global emphasis on protecting the night sky, reducing upward light through physical shielding structures or asymmetrical light distribution designs has become a crucial indicator of a solution's professionalism. This is not only for visual comfort but also for respecting the ecological environment.

Balance of Color Rendering and Color Temperature: The choice of color temperature is crucial for different environments (such as ports, gardens, or urban main roads). From warm low color temperatures to cool high color temperatures, this reflects a deep understanding of environmental atmosphere and visual recognition.

II. Reliability Engineering in Extreme Environments

Outdoor environments are complex and ever-changing, and lighting equipment must withstand the harsh challenges of high temperatures, high humidity, salt spray, and strong ultraviolet radiation. Everlite LED Lighting Co., Limited. consistently adheres to high-standard physical protection standards in its manufacturing and testing processes.

Efficient Thermal Management Architecture: Heat dissipation is key to determining the lifespan of outdoor LED lighting. By using high thermal conductivity materials combined with fluid dynamics-designed heat sinks, the chip junction temperature can be effectively reduced, ensuring minimal light decay during continuous operation.

Structural Protection and Sealing Technology: Outdoor lighting must possess strong impact resistance and excellent dustproof and waterproof performance. Through the use of high-performance polymer sealing materials and precision die-casting processes, the internal circuitry remains stable even in strong winds, heavy rain, or dusty environments.

Corrosion Resistance Treatment: For coastal areas or industrial environments, the surface powder coating and anodizing processes require extremely strong adhesion and oxidation resistance to prevent system failure caused by casing corrosion.

III. Intelligent Integration and Energy Management

Modern Outdoor Lighting Solutions are no longer isolated luminaires, but important nodes in the Internet of Things (IoT) system.

Dynamic Dimming Technology: Intelligent dimming based on time periods, pedestrian traffic, or ambient light sensing enables on-demand lighting, significantly reducing unnecessary energy consumption.

Remote Monitoring and Fault Warning: Through integrated communication modules, maintenance personnel can monitor the operating status of each light in real time from the management end. This shift from "reactive maintenance" to "proactive operation and maintenance" is the core value of the Everlite technology solution.

System Compatibility: The solution must have good protocol compatibility (such as DALI, 0-10V, or various wireless protocols) to ensure seamless integration into the overall framework of a smart city.

IV. Core Performance Comparison Analysis Table

| Performance Metric |

Conventional Lighting Solutions |

Everlite Professional Solutions |

| Optical System |

Simple reflectors; significant light spill and loss. |

Customized secondary optical design; precision beam control with maximum utilization. |

| Thermal Management |

Passive dissipation via basic housing; prone to overheating. |

Integrated thermal simulation systems; precise temperature rise control for chip longevity. |

| Material Selection |

Standard aluminum; limited resistance to oxidation and corrosion. |

High-grade die-cast aluminum with specialized weather-resistant and anti-corrosive coatings. |

| Smart Integration |

Limited to basic on/off switching. |

Deep integration with smart sensors, dimming drivers, and IoT communication protocols. |

| Light Quality |

Fluctuating Color Rendering Index (CRI); high glare levels. |

High CRI and low-glare design; optimized for superior visual clarity and safety. |

| Total Lifecycle Cost |

Low initial cost but high frequency of maintenance and energy waste. |

High stability and efficiency; significantly lower long-term Operation & Maintenance (O&M) costs. |

V. Frequently Asked Questions (FAQ)

Q1: Why is thermal management more important than brightness in outdoor lighting solutions?

A: Brightness is fundamental, but thermal management determines the sustainability of that brightness. Poor heat dissipation can lead to severe light decay and even burnout of the LED chips due to high temperatures. A professional solution prioritizes heat dissipation to ensure consistent light color throughout the product's lifespan.

Q2: How to choose the appropriate outdoor lighting solution based on different regional environments?

A: Environmental factors are the core basis for selection. For example, coastal areas require enhanced salt spray corrosion resistance; high-latitude, cold regions require consideration of the low-temperature starting performance of electronic components and the crack resistance of the casing. With over ten years of experience, Shishang Everlite provides targeted material optimization solutions for different geographical regions.

Q3: What is "light pollution," and how can it be avoided in outdoor lighting design?

A: Light pollution mainly refers to excess light that spills outside the target area. Methods to avoid it include using cut-off type luminaires, precisely adjusting the projection angle, and setting reasonable power reduction during nighttime hours to ensure lighting only appears where needed.

Q4: Are more integrated functions in outdoor lighting products always better?

A: Not necessarily. A truly professional solution emphasizes "precise matching of functions and needs." Too many redundant functions increase system complexity and failure rate. Shishang Everlite's R&D logic is based on modular configuration according to actual application scenarios, ensuring high performance and reliability.

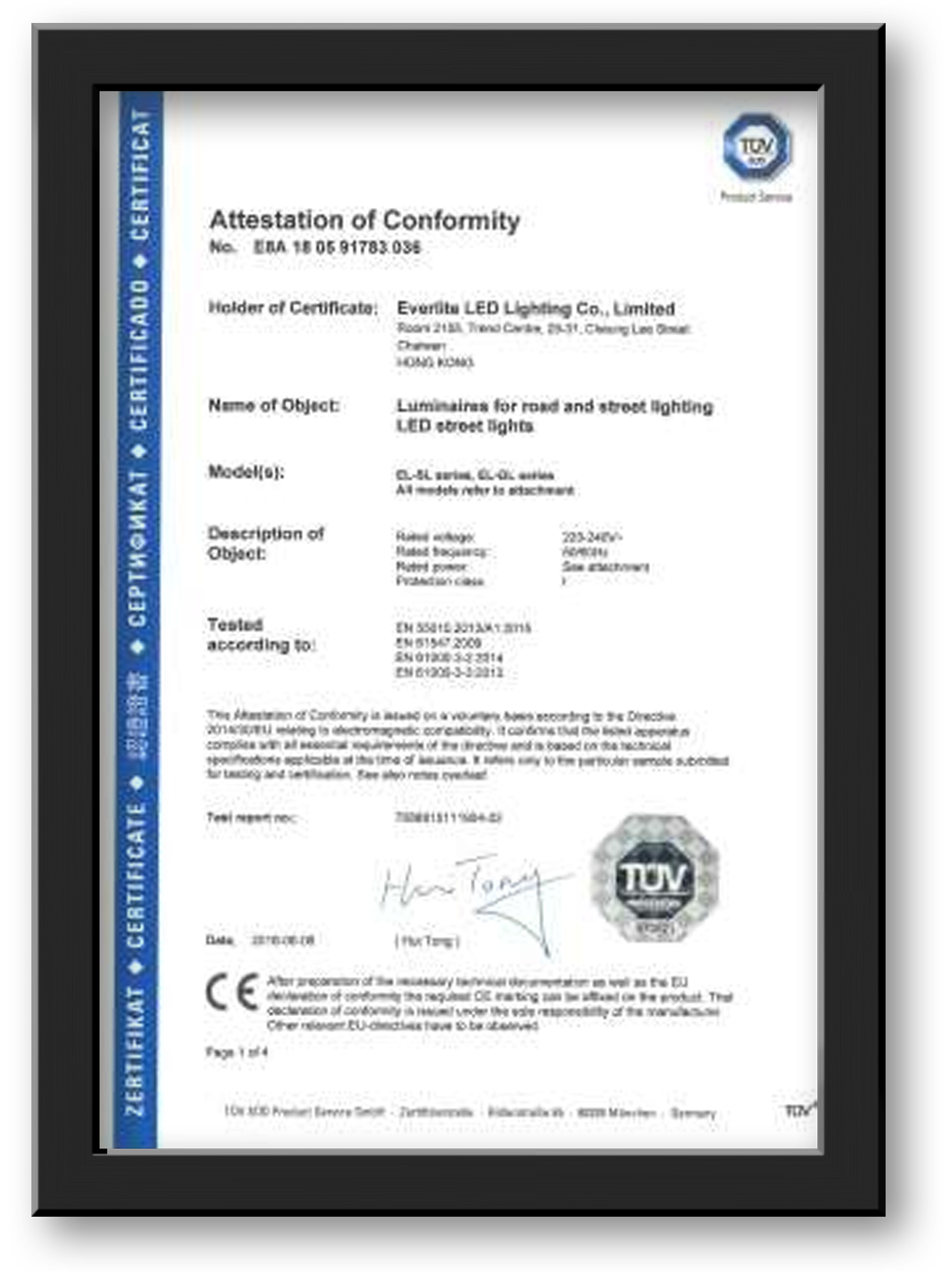

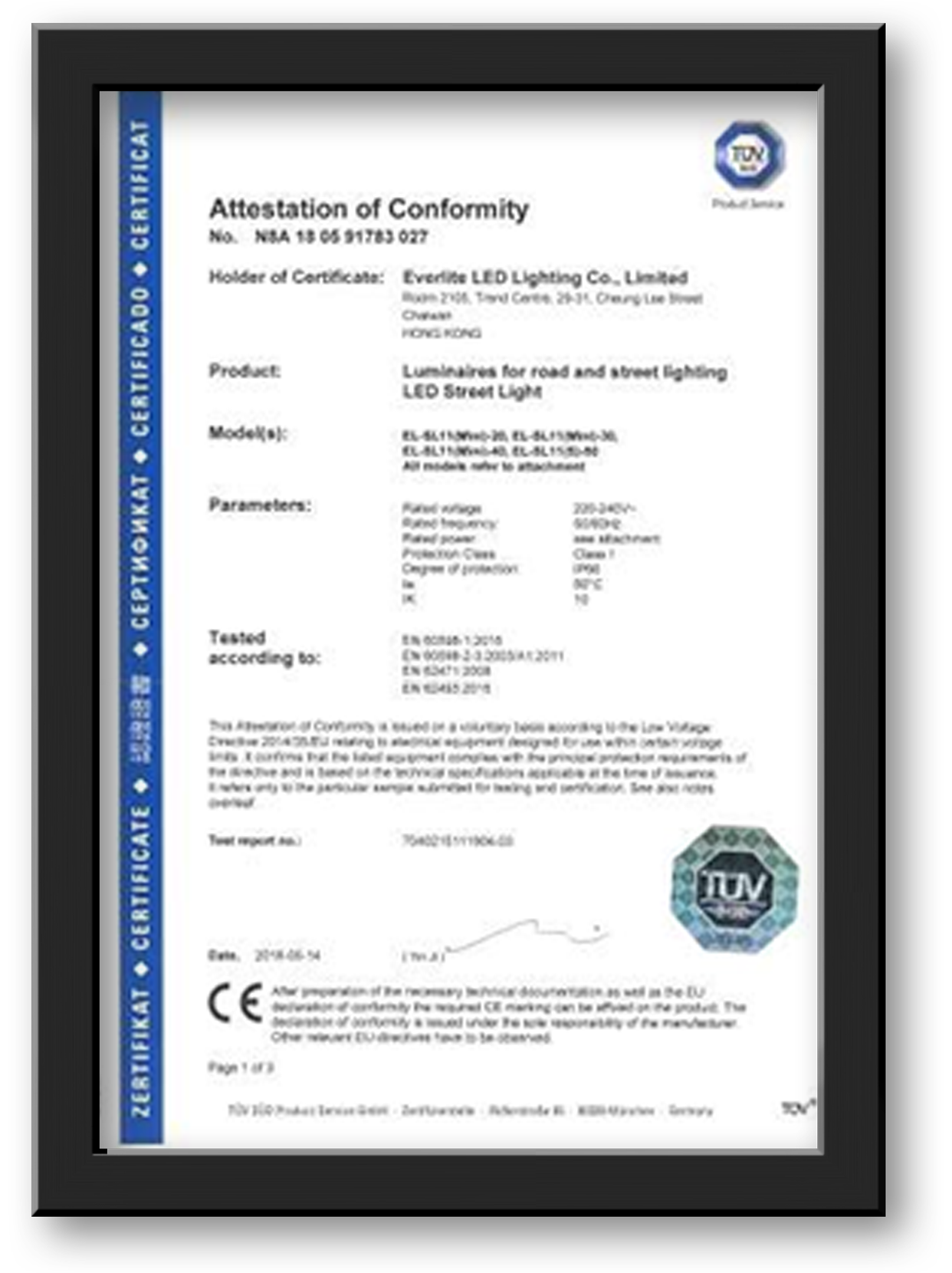

Q5: How does Everlite LED Lighting Co., Limited. guarantee solution quality throughout the entire industry chain?

A: The company integrates R&D, manufacturing, testing, and certification. This closed-loop model ensures that every link, from the initial design concept to the final product, operates within a controlled quality system. In particular, the in-house testing and certification process allows for pre-verification of the solution's extreme durability.